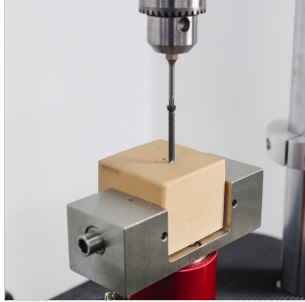

Measures driving, stripping, and removal torque of bone screws.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Standard

YY/T 1506, ASTM F543:

The standard specifies the torque required to measure the torque required to screw a metallic bone grafting screw into and out of a standardized material in order to confirm the consistency of the product under test. A constant force of 11.17N was maintained at a rate of 3r/min, with 4 turns screwed in and then 4 turns screwed out.

Kyle Measurement & Control M-100T is lightweight, easy to operate and precise in control, suitable for bone nail testing. We provide you with professional test fixtures to meet the standard requirements, as well as accurate and effective test program (SOP), and optional data post-processing software to reduce the difficulty of data processing to help analyze the mechanical properties of metal bone screws.

Product features:

1. Diversification of functions, can realize a multi-functional, multi-purpose machine

2. Humanized interface design, easy to operate

3. Industrial appearance design, beautiful and generous, focusing on user experience

4. Professional high-performance control system to control the coordinated action of dual motors

5. Imported customized high sensitivity load element, imported screw to ensure accurate displacement.

6.Professional fixture for different testing modes.

7. Simple and easy to operate, highly simplified control system puts all the cumbersome settings in the background to complete, one-button startup.

8. Multi-curve drawing mode, easier to control the testing process.

9. metal bone screw rotating (screwing in and out) torque testing machine test method using full Chinese operation and display interface, display information intuitive and easy to read, multi-key operation, with Chinese display interface, make your operation more simple, completely according to the customary prompts interface sequence operation, complete the system parameter settings. Adopt AC servo motor, precision reducer transmission, with loading uniformity, stability, no impact phenomenon, data collection and control of accurate characteristics.

Main technical parameters:

1. Unit: N-m

2.Resolution: 0.001N.m

3... Torque range: 0-10N.m

4. Torque sensor accuracy level: less than 0.5%F.S.

5.Speed accuracy: ±0.01mm/min

6. Axial force sensor: 2000N (taking into account the axial pull-out force test)

7. Pressure sensor accuracy level: less than 0.5%F.S.

8. Pressure sensor resolution: 0.001N

9. Linear displacement sensor: range above 50m.

10. Displacement sensor accuracy level: less than 0.5%F.S.

11. Displacement sensor resolution: 0.01mm

12. Torsion angle sensor: 999999 °

13. Torsion angle accuracy: ±0.2°.

14. Torsion speed: 1r/min ~ 30r/min within any choice

15. Effective stroke: 500±10mm (can be increased according to demand)

16. Torque resolution 1/±1000000F.S

17.Relative error of torque display value ≤±0.2%.

18.Torsion angle resolution 0.001°.

19. Relative error of torsional angular velocity within ±0.5% of set value

20. Coaxiality of the two collets ≤ ¢0.2mm

21 machine power ≈ 0.4kW

22. Power supply voltage ~220V±10% 50Hz (must be reliably grounded)

Từ chối trách nhiệm: Nội dung trên chỉ dành cho tham khảo và giao tiếp giữa những người trong ngành và không đảm bảo tính chính xác hoặc đầy đủ của nó. Theo luật pháp và quy định có liên quan và các quy định của trang web này, các đơn vị hoặc cá nhân mua các mặt hàng liên quan phải có trình độ và điều kiện trình độ hợp lệ.

Điện thoại công ty

+86-21-6420 0566

Thời gian làm việc

Thứ Hai đến Thứ Sáu

Điện thoại di động:

13816217984

Email:

info@qinsun-lab.com